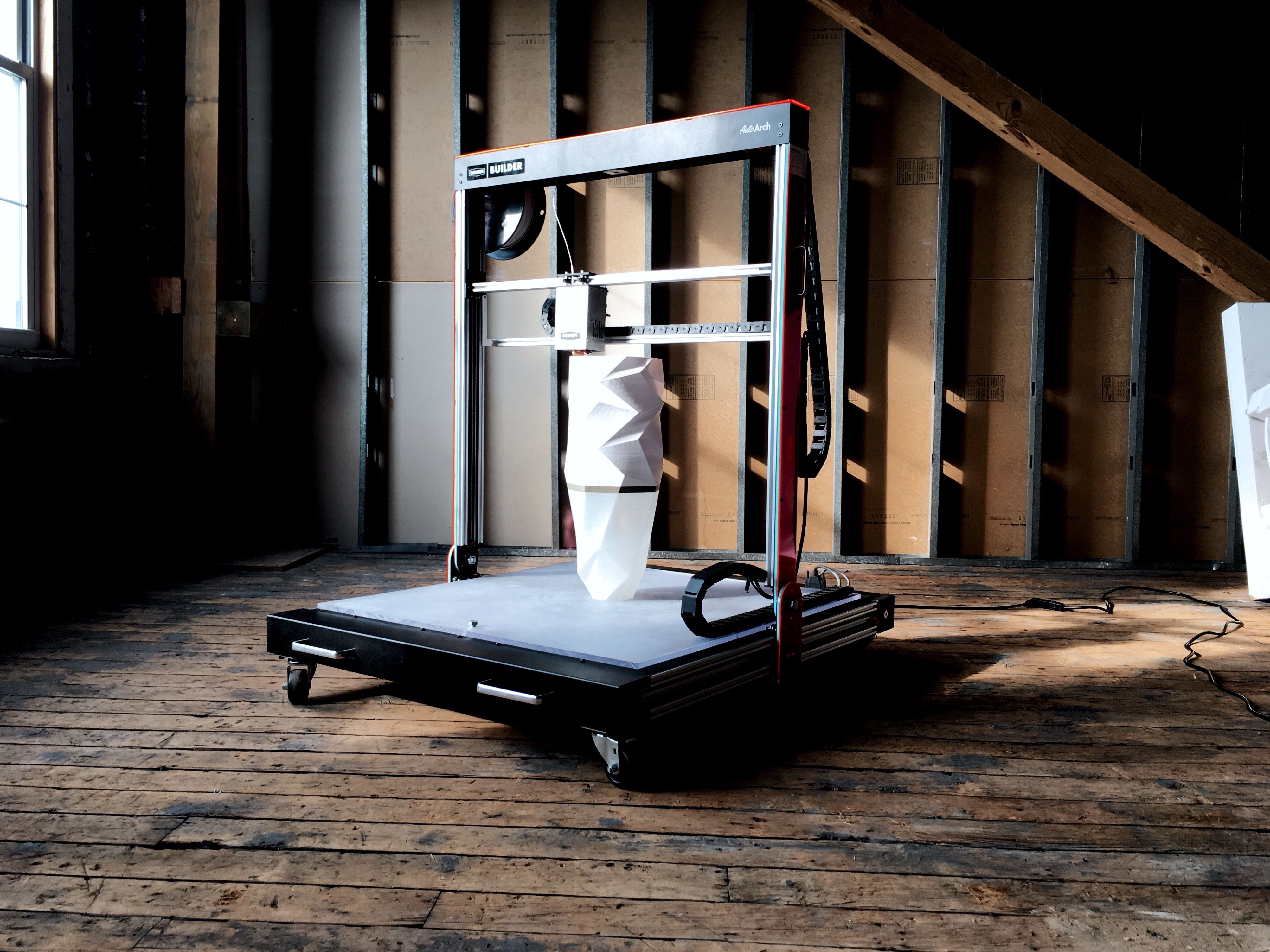

Six years building a printer. Eight prototypes. 124 hours of printing.

Six years building a printer. Eight prototypes. 124 hours of printing.

Not a miniature. Not a prototype. A full-sized, functional chair that could hold a person. A chair that took advantage of what 3D printing does best—complex forms, curved shapes, layer-by-layer growth—without fighting the process.

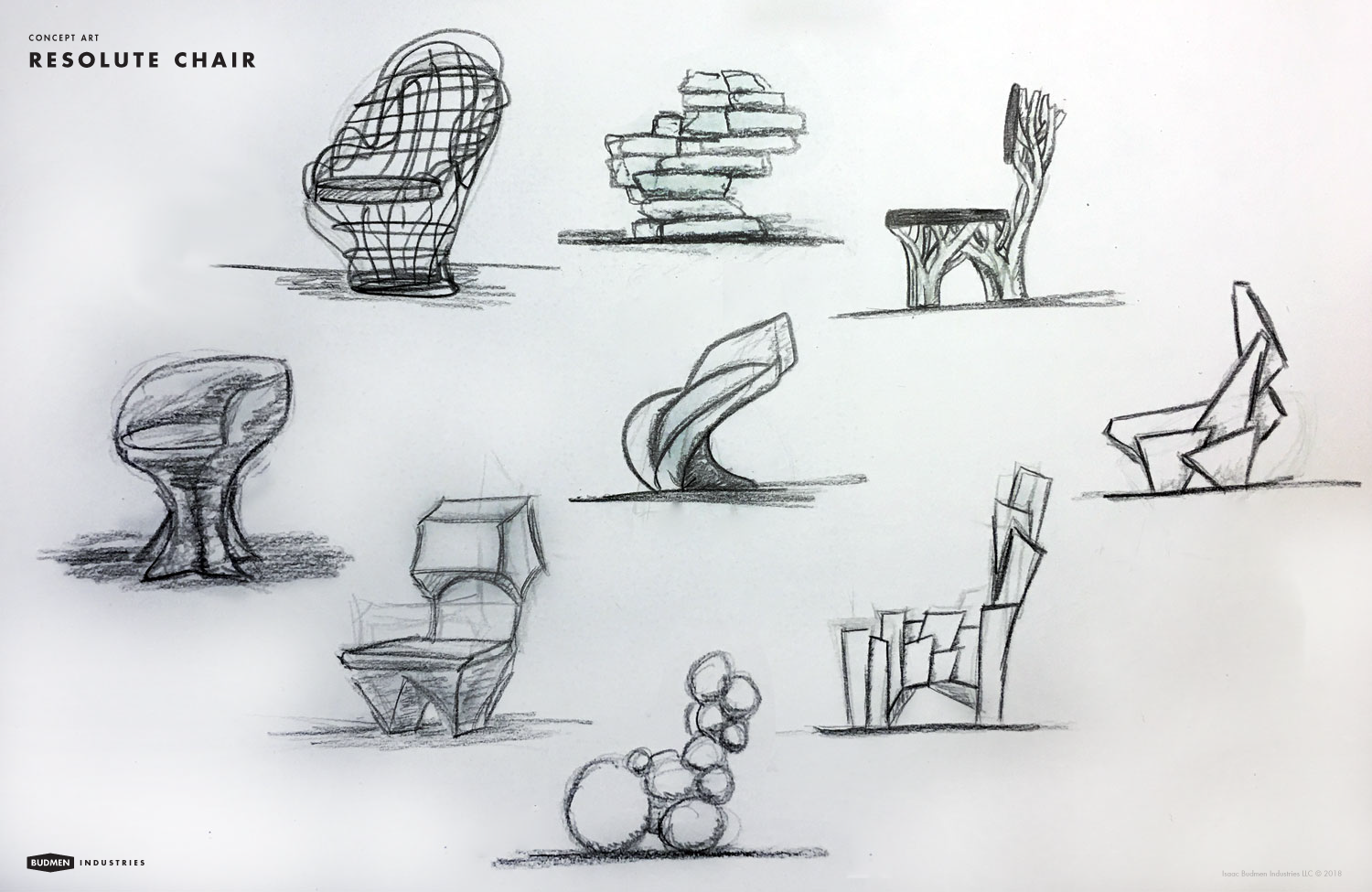

Nature's self-supporting structure

The same principle applied to a chair

The tree structure wasn't chosen for aesthetics, though it is beautiful. It was chosen because it solved our core constraint: how to 3D print a chair without support material.

50% - Trunk growing

Six years from question to answer. Resolute.

| Title | Resolute Chair |

|---|---|

| Year | 2016 |

| Category | Furniture |

| Technology | Large-scale FDM 3D printing (Budmen Progress™) |

| Materials | PLA (biodegradable plastic), structural resin coating |

| Print Time | 124 hours |

| Development Time | 6 years |

| Printer Versions | 8 iterations of the Progress printer |

| Finish | Hand-sanded, resin-coated with textured finish |

| Weight Capacity | 250+ lbs |

| Design Principle | Biomimicry - tree structure (roots, trunk, canopy) |

| Status | One-of-one piece |