LESSON 4

Preparing your Model for 3D Printing

In this unit you will learn how to set up a 3D print job by creating a G-code file, the different parameters of a 3D print, and tips and tricks for successful prints.

Now that we have a 3D model, we need to set up the print job. The 3D model file exists on your computer simply as digital information. In order to print it, we need to slice the model into directions that the 3D Printer can follow. These directions are known as G-code and are generated by slicing software.

When slicing a 3D model, there are several factors you can control that will influence the performance of your 3D printed object. These include object orientation, object resolution, infill percentage, object shells, and support material.

Step 1: Position the Digital Object

First, open your 3D model (STL file) in the slicing software. When the object appears in the software, orient it on the build platform.

The position of an object on the build platform can have a dramatic impact on the print's end result. The orientation of your print affects print time, success, accuracy, and strength. Orient your model so a flat surface is facing down on the build platform.

Dudlee our robot showing you the correct way to orient your object on the build plate in the slicing software.

Dudlee our robot showing you the correct way to orient your object on the build plate in the slicing software.

The Buildini™ prints in horizontal layers, building the object from the bottom up. As a rule of thumb, fewer vertical layers make for a stronger object that will also print faster.

Step 2: Object Resolution and Layer Height

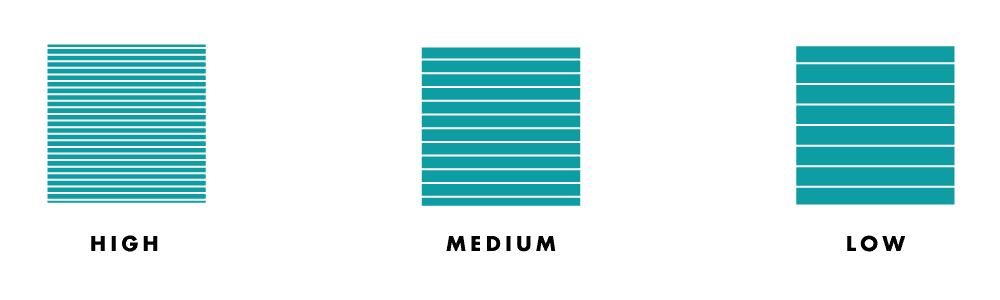

Just like a digital photograph, a 3D printed object has a resolution. High-resolution photos are made up of densely packed pixels, creating a smooth picture. In contrast, low-resolution photos use fewer pixels, creating a pixelated image.

In 3D printing, object resolution corresponds to layer height, which is measured in millimeters or microns. Smaller layer heights result in higher resolution objects with smooth surfaces but will increase print time.

Example of low, medium, and high-resolution objects.

Example of low, medium, and high-resolution objects.

Below is a chart of different resolutions and the typical layer heights for each classification:

| Resolution | Layer Height | Relative Print Time |

|---|---|---|

| Low | 0.3mm-0.4mm | Short |

| Medium | 0.2mm-0.3mm | Medium |

| High | 0.1mm-0.2mm | Long |

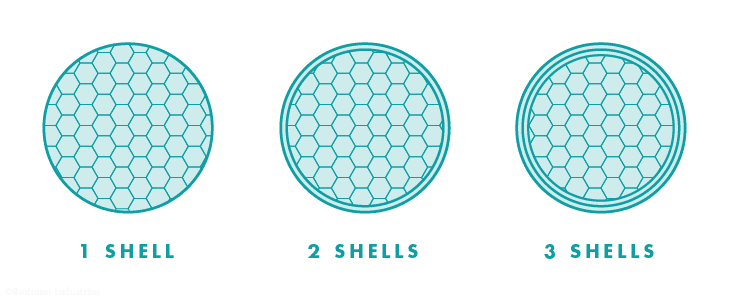

Step 3: Object Shells

Object shells, or perimeters, are the outer layers of the print that make up the walls of your object. The more shells, the stronger your object will be. Use fewer shells for display items, such as sculptures, and more shells for objects that need to withstand pressure or stress, like mechanical parts. Adding shells will also increase print time and material usage.

Step 4: Infill

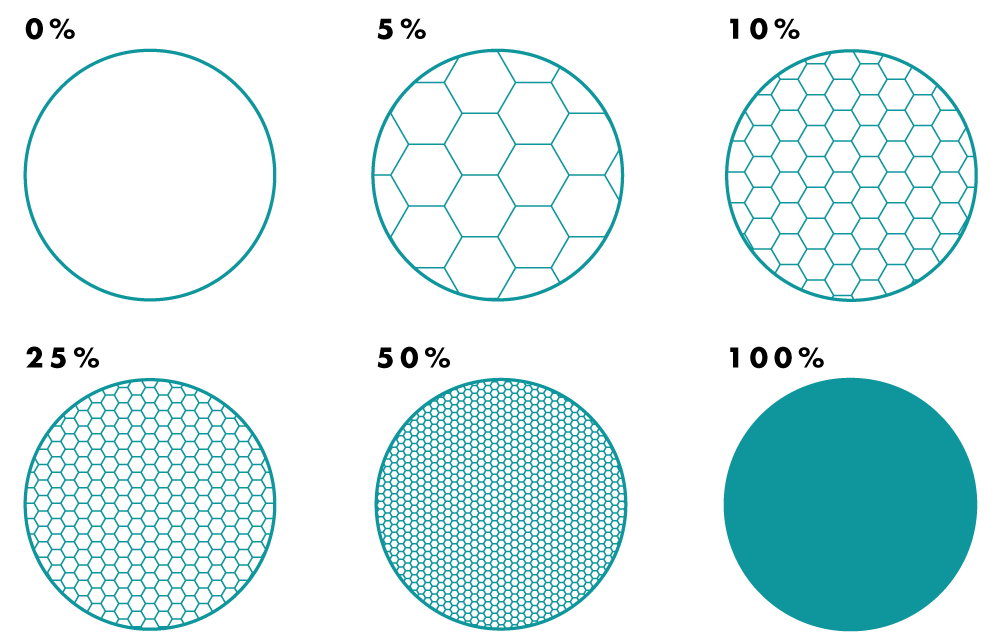

The object infill refers to the inside structure and density of a 3D printed object. It is measured in percentages, where 100% infill creates a solid object, and lower percentages create lighter, hollow interiors.

A diagram of different infill densities.

A diagram of different infill densities.

Light-use and decorative objects can have lower infill densities (5%-20%), while objects that need to stand up under heavy use should have a higher infill density (20% or higher).

Step 5: Support Material and Raft

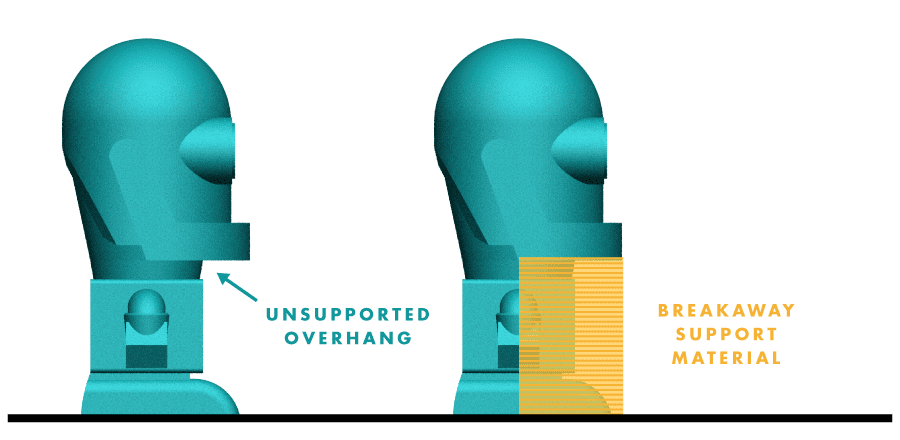

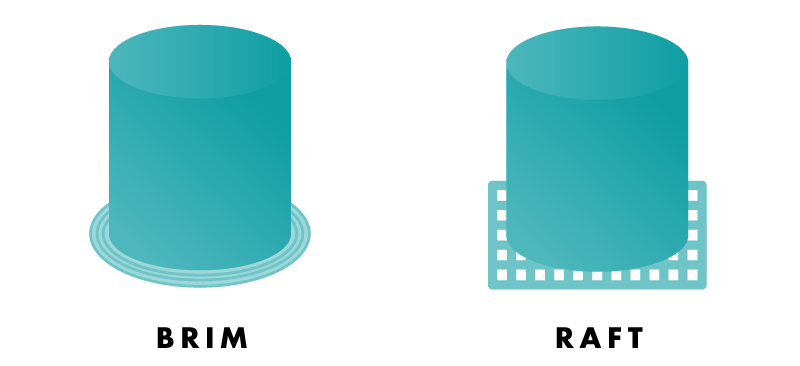

Objects with overhangs or bridges that exceed 45° may require support material. Support material acts as a scaffold, and after printing, it can be easily removed. You can also use a raft for better adhesion on objects with small features or challenging material types.

Dudlee, our robot, showcasing an object 3D printed with support material

Dudlee, our robot, showcasing an object 3D printed with support material

Example of an object printed with a raft.

Example of an object printed with a raft.

Step 6: Slice and Save

After adjusting your settings, slice your object to generate a G-code file. Save the G-code file to your computer or SD card, and you’re ready to print with your 3D printer!

Click here to go to the next module: 3D Printing Your ObjectVocab Words

- Build Platform: The surface where an object is 3D printed. Also called build plate or bed.

- Infill: Internal support structure of FFF printed objects; the higher the percentage of infill, the denser the object.

- Layer Height: Height of the horizontally printed layers of a 3D printed object, typically measured in millimeters or microns.

- Raft: Removable and discarded latticework of filament underneath an object to help with warping and bed adhesion.

- Slicer: Software that converts STL files or other 3D model formats into G-code files for 3D printing.

- Slicing: Process of converting a 3D model into G-code files containing fabrication instructions for a 3D printer.

- STL File: Digital file format for a 3D model, imported into a slicer to convert it to G-code.

- Support: Removable and discarded 3D printed material used to successfully fabricate overhangs, bridges, and negative space.